Square D Pressure Switch Manual⁚ A Comprehensive Guide

This comprehensive guide will delve into the world of Square D pressure switches‚ providing you with a thorough understanding of their features‚ benefits‚ applications‚ and troubleshooting techniques. We will cover various types of Square D pressure switches‚ including the popular Pumptrol series‚ and discuss their role in residential‚ commercial‚ and industrial settings. This manual serves as a valuable resource for anyone seeking to learn more about Square D pressure switches and their proper use.

Introduction

Square D pressure switches‚ a cornerstone of reliable pumping systems‚ play a pivotal role in ensuring the smooth and efficient operation of water pumps in various applications. These switches‚ renowned for their durability and performance‚ are designed to monitor and control the pressure within a system‚ automatically activating or deactivating pumps based on predetermined pressure thresholds. Their importance extends across diverse sectors‚ from residential homes to large-scale industrial facilities‚ making them indispensable for maintaining optimal water pressure and protecting pumps from damage.

This manual serves as a comprehensive guide to Square D pressure switches‚ providing users with a deep understanding of their functionality‚ operation‚ and maintenance. We will explore the core principles behind pressure switch operation‚ delve into the intricacies of Square D’s Pumptrol series‚ and highlight the unique features and benefits that set these switches apart. Additionally‚ we will address common applications‚ troubleshooting techniques‚ and safety guidelines to ensure optimal use and longevity of Square D pressure switches.

Whether you are a homeowner seeking to understand the workings of your well pump system or a professional installer tasked with setting up a complex industrial pumping network‚ this manual will equip you with the knowledge and insights necessary to confidently utilize Square D pressure switches. By grasping the concepts outlined within these pages‚ you can ensure efficient‚ reliable‚ and safe operation of your pumping systems‚ maximizing their lifespan and minimizing potential issues.

Understanding Pressure Switches

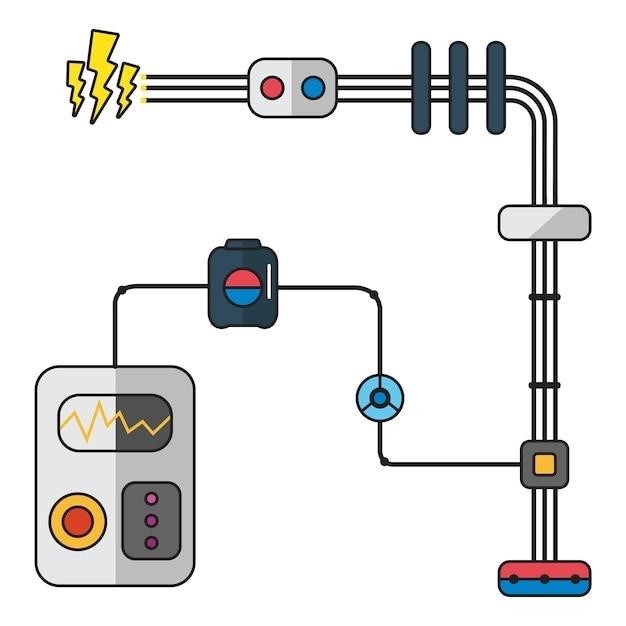

Pressure switches are essential components in fluid-handling systems‚ acting as the control mechanism for pumps‚ compressors‚ and other equipment. They function by sensing the pressure within a system and triggering an electrical signal based on predefined pressure levels. This signal can then activate or deactivate pumps‚ compressors‚ or other devices‚ ensuring that the system operates within desired pressure ranges.

A pressure switch typically comprises a sensing element‚ a diaphragm or piston‚ that responds to pressure changes within the system. This change in pressure causes the sensing element to move‚ activating an internal switch mechanism. The switch mechanism‚ usually a set of electrical contacts‚ closes or opens an electrical circuit‚ initiating or terminating the operation of the connected equipment.

Pressure switches are characterized by two key pressure settings⁚ cut-in pressure and cut-out pressure. Cut-in pressure refers to the pressure level at which the switch activates‚ turning on the pump or compressor. Cut-out pressure‚ on the other hand‚ represents the pressure level at which the switch deactivates‚ shutting off the pump or compressor. The difference between these two pressure settings is known as the differential pressure‚ which determines the pressure range within which the system operates.

Square D Pumptrol Pressure Switches

Square D Pumptrol pressure switches are a widely recognized and trusted brand in the field of water pump control systems. These switches are specifically designed to monitor and regulate pressure within water systems‚ ensuring efficient and reliable operation of pumps. The Pumptrol line boasts a comprehensive range of pressure switches‚ catering to diverse residential‚ commercial‚ and industrial applications.

Square D Pumptrol pressure switches are renowned for their durability and reliability. They are constructed using high-quality materials and components that withstand demanding conditions‚ making them ideal for both indoor and outdoor installations. The switches are also equipped with robust electrical contacts‚ capable of handling high switching currents‚ ensuring long-lasting performance.

Furthermore‚ Square D Pumptrol pressure switches are designed with user-friendliness in mind. They feature clear and concise labeling‚ making it easy to identify different settings and adjust pressure levels. The switches also include safety features‚ such as over-pressure protection‚ to prevent damage to the pump and system. Their versatility and robust construction make them a preferred choice for various water pump control applications.

Features and Benefits

Square D pressure switches offer a range of features and benefits that contribute to their efficiency‚ reliability‚ and ease of use. One key advantage is their corrosion-resistant plating‚ ensuring long-lasting performance even in harsh environments. This environmentally responsible design complies with RoHS standards‚ promoting sustainability. The switches also incorporate holdtight terminations‚ which securely hold ground wire strands‚ reducing wiring time and ensuring reliable grounding.

Square D pressure switches are built for durability and dependability. They feature heavy-duty‚ thick contacts designed for extended electrical life‚ ensuring consistent and reliable operation over time. The diaphragm-actuated mechanism provides accurate pressure sensing‚ responding reliably to pressure fluctuations within the system. Additionally‚ the adjustable differential allows for precise control of the pressure cut-in and cut-out points‚ optimizing pump operation for specific applications.

Another notable feature is the optional manual on/off switch‚ often found in the 9013 series. This lever allows for manual control of the pump‚ providing flexibility and convenience for specific applications. The manual on lever enables manual pressurization of the system‚ eliminating the need for automatic cycling during initial startup. These features combine to make Square D pressure switches a reliable and versatile choice for a wide range of water pump control systems.

Types of Square D Pressure Switches

Square D offers a variety of pressure switches designed to meet specific application needs. One popular series is the Pumptrol 9013‚ known for its reliability and versatility in residential‚ commercial‚ and industrial settings. The 9013 series features adjustable differential‚ allowing for customization of the pressure cut-in and cut-out points; This series also offers an optional manual on/off lever‚ providing flexibility for manual control of the pump.

The FSG2J21M4CP electromechanical pressure switch‚ also part of the Pumptrol series‚ is another widely used option. This switch is designed for use in residential‚ commercial‚ and industrial pumping applications and features a 30 psi to 50 psi pressure range. Its manual on lever allows for manual pressurization of the system‚ eliminating the need for automatic cycling during initial startup.

Square D also offers a range of pressure switches designed for specific applications. The 9012 Type G pressure switches are control circuit rated devices used in pneumatic or hydraulic systems‚ providing protection and control in various machine and process applications. The 9013FRG reverse action pressure switch triggers an alarm based on low pressure conditions‚ enhancing system safety and preventing potential problems. Square D’s diverse selection ensures that you can find the ideal pressure switch for your specific needs.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are crucial for ensuring the optimal performance and longevity of your Square D pressure switch. Start by visually inspecting the pump system for any signs of leakage. This could indicate a problem with the pressure switch or other components in the system. Next‚ use a pressure gauge to check the pressure switch settings and compare them to the recommended values for your specific application. If there are any discrepancies‚ adjust the settings accordingly.

If you encounter issues with the pressure switch‚ it’s essential to troubleshoot the problem systematically. First‚ ensure that electrical power is available to the switch and that circuit breakers are not tripped. Check the wiring connections for any loose or damaged wires. If the pressure switch is not responding to pressure changes‚ it might be malfunctioning. In such cases‚ consider replacing the switch with a new one.

To prevent potential problems‚ it’s recommended to perform regular maintenance checks on the pressure switch. This includes cleaning the switch contacts‚ checking the diaphragm for wear and tear‚ and ensuring proper lubrication of moving parts. By following these maintenance guidelines and addressing any issues promptly‚ you can keep your Square D pressure switch operating reliably for years to come.

Common Applications

Square D pressure switches find widespread application in a variety of settings‚ thanks to their reliability and versatility. One of the most common uses is in residential water well systems. The pressure switch controls the pump‚ turning it on when water pressure drops below a predetermined level and turning it off when the pressure reaches the desired level. This ensures that the well pump operates efficiently and provides a consistent water supply to the home.

Beyond residential applications‚ Square D pressure switches are also essential components in commercial and industrial settings. They are used in water supply systems‚ irrigation systems‚ air compressors‚ and other equipment that requires precise pressure control. In industrial settings‚ these switches are often employed to monitor and control pressure in hydraulic and pneumatic systems‚ ensuring optimal operation and preventing equipment damage.

Square D pressure switches are also used in a variety of other applications‚ such as controlling the flow of liquids in chemical processing plants‚ regulating the pressure in compressed air systems‚ and monitoring the pressure in HVAC systems. Their ability to withstand harsh environments and provide reliable performance makes them suitable for a wide range of industrial and commercial applications.

Safety Instructions

When working with Square D pressure switches‚ it is crucial to prioritize safety to prevent accidents and ensure proper operation. Always disconnect power to the switch before attempting any repairs or adjustments. Never work on a live circuit‚ as this poses a significant risk of electric shock. Before beginning any work‚ ensure the area is well-lit and free of clutter to prevent tripping hazards. Wear appropriate safety gear‚ including insulated gloves and safety glasses‚ to protect yourself from potential hazards. Always follow the manufacturer’s instructions in the user manual to ensure proper installation and maintenance.

If you are unsure about any aspect of the installation‚ maintenance‚ or repair process‚ seek assistance from a qualified electrician. Avoid using the switch for any application other than its intended purpose. Overloading the switch can result in damage or malfunction. Inspect the switch regularly for signs of wear‚ damage‚ or corrosion. If you notice any issues‚ replace the switch immediately to prevent potential hazards. By adhering to these safety precautions‚ you can ensure a safe and reliable operation of your Square D pressure switch.

Remember‚ safety is paramount when working with electrical equipment. Always exercise caution and follow the instructions provided in the user manual. If you have any doubts‚ consult a qualified professional.

Frequently Asked Questions

Here are some common questions and answers related to Square D pressure switches⁚

- Q⁚ What is the difference between a 30/50 and a 40/60 pressure switch?

- A⁚ The numbers refer to the cut-in and cut-out pressure settings. A 30/50 switch will turn the pump on at 30 psi and off at 50 psi‚ while a 40/60 switch will turn the pump on at 40 psi and off at 60 psi. You can adjust the pressure settings based on the specific needs of your system.

- Q⁚ How do I adjust the cut-in and cut-out pressure on a Square D pressure switch?

- A⁚ The adjustment process varies depending on the model‚ but typically involves turning a large nut on top of the center spring. Turning the nut clockwise increases the pressure‚ while turning it counterclockwise decreases the pressure. Consult your specific switch’s user manual for detailed instructions.

- Q⁚ What are the most common applications for Square D pressure switches?

- A⁚ Square D pressure switches are widely used in residential‚ commercial‚ and industrial settings‚ primarily for controlling water pumps in well systems‚ irrigation systems‚ and other fluid-handling applications. They are also used for controlling air compressors and other pressure-sensitive systems.

- Q⁚ How do I troubleshoot a Square D pressure switch?

- A⁚ Start by visually inspecting the switch for signs of damage or corrosion. Check the wiring connections and ensure they are secure. Use a pressure gauge to verify the actual pressure settings and compare them to the desired settings. If you suspect a malfunction‚ consult your user manual or contact a qualified electrician for assistance.